-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Types and Applications of Mag Drive Couplings

Mag Drive Coupling is already recognized as one of today's leading technologies in a broad range of industries. This MagLand unique device transfers power from a motor to a pump without the need for traditional seals or packing. We will go into an archive of benefits associated with using Magnetic coupling along deliberations on how it works and obviously in which fields can this be applied.

Safety: Mag drive coupling offers unrivalled levels of safety. Mag drive coupling helps solve this problem because it is far superior to traditional seals and packing materials, allowing hazardous fluids from leaking out of the equipment. This MagLand reduces accidents and also increase safety to workers.

Although levels of efficiency and reliability are part of this, the Linear magnetic coupling also provides safety. This is not only preventing operational failures, but also increases the life of each component within a system by eliminating maintenance-heavy components such as packing and mechanical seals.

Best known as a magnetic coupling price, it is the use of magnetic fields to transmit power! Those MagLand two magnetically-coupled rotors allow power to flow from one end of the system to the other with no physical interaction. As a consequence of this special way to work, it makes the overall system far more robust and secure when no physical (mechanical) parts connect between motor and pump.

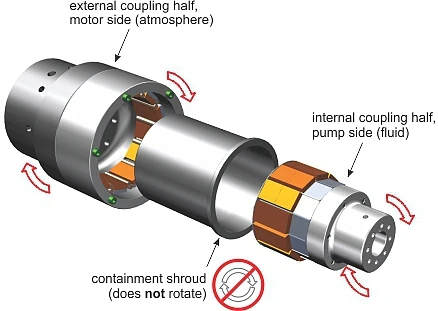

Mag drive coupling functions through the use of strong magnetic fields to transmit torque from motor to pump. There are two magnetic rotors involved in this process - the driving rotor and driven rotor. The driving rotor is connected to the motor shaft and driven rotor to the pump shaft.

IFAS Figure 3 - 'EMI' being produced in the driving rotor, inducing it within a synthetic electric field to its driven counterpart. This in turn creates a axial magnetic coupling field which interacts with the driving rotor to facilitate power transfer without any mechanical contact between both rotors.

For many industrial applications, mag drive couplings are the best solution available when dealing with toxic or unsafe substances. It can be used in the centrifugal, turbine and positive displacement pumps. Mag drive coupling is particularly useful for pumping chemicals, acids and so on bearing with them a high level of safety and security.

Magland huge Mag drive coupling covers 40,000 square meters outfitted 300 pieces high-end processing equipment including robotics automated machinery. technology allows accurate efficient production processes guarantee top product quality.

Leveraging magnetic circuit simulation software, Magland provides customized services meet clients particular Mag drive coupling. Magland specializes customized magnetic solutions. product created optimized meet specific requirements our clients. addition, adhering flexibility, company accommodate requests customization works provide magnetic assemblies exactly match customer specifications.

Magland Mag drive coupling technological advancement works academic research institutions remain forefront advancements magnetism. commitment ensures cutting-edge magnet assemblies created meet unique needs customers.

Magland maintains strict quality control measures Mag drive coupling production process beginning screening raw material final inspection finished product. product subjected extensive testing, ensuring they satisfy technical environmental demands customers.

There are a lot of parts at play and the installation of mag drive coupling requires strict attention to detail so as not leave loose ends when securing all the components. Before installation, make correlate that the motor and pump shafts are parallel as well as their magnetic fields facing each other.

The use of electromagnetic coupling alignment tools should be used during installation for accurate shaft alignment and proper placement of magnetic fields. It is crucial after fitting to maintain the system for its optimal function with routine checks and maintenance.

Although mag drive coupling performs better in terms of maintenance compared a traditional pump, you cannot ignore the fact that regular servicing is necessary to maintain its efficiency. Currently it is recommended that. COMo be subject, all annual major service checks to check absolutely all elements of seals and bearings. In addition, it is essential to ensure the alignment of the pump properly and magnetic coupling functioning correctly.

While choosing gates mag drive coupling to ensure the peel growth you cannot compromise on product quality. It is critical that high-quality materials are used during the manufacturing process as any leaks or malfunctions could directly lead to safety and environmental hazards.

Mag drive coupling is a versatile coupling and its applications extends across range of industries such as chemical processing, pharmaceuticals, water treatment etc. Commonly used where safety and reliability are paramount eg when handling toxic, harmful or corrosive materials but also in sanitary applications such as food industries to prevent contamination by sealing on pump.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd