-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Exploring The Mysteries Of Permanent Magnetic Couplings

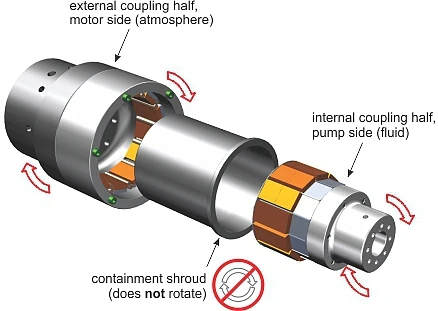

Term magnetic couplings, have you ever heard of it! These amazing tools act as a conduit to carry energy and information between two rotating machines without any contact points. While they may appear normal upon first glance, these unassuming rings hold a not so secret power: their ability to tap into magnetic fields to generate motion and transfer energy from one device onto another. This post will explore some of the benefits, but also applications using this incredible technology!

One of the main benefits permanent magnetic couplings is that they can be run without render with a mechanical seal, which offers installation capabilities in traditional common couplers. Why mechanical seals are important Mechanical seals perform a very vital function in creating and maintaining an effective seal which prevents any kind of leakage as well helps to retainfluids during regular operation. The Problem: But those seals can degrade over time and result in failure. On the other hand, a permanent magnetic coupling works based on using magnetic force to stop two closely spaced objects from rotating. This not only lowers maintenance and repair costs, but also prevents future cost.

Permanent magnetic couplings are a technology that has gradually come to life with innovation influencing its evolution. Newer versions are said to come with increased power transmission efficiency and improved torque capacities. The magnetic couplings have been utilized in many industries and industrial applications as the technology progressed. Also, modern magnetic couplings work non-invasively so that they do not affect the performance of a surrounding device.

When it comes to working these technologies with electrical and magnetic, the safety is above all. Unlike traditional couplings, permanent magnetic coupling use physical interfaces that can leak or contaminate places and hence these have safety feature which need not to be incorporated separately. These couplings disengage themselves in the event of a power loss so as to not permit any unwanted or involuntary release or transfer of fluid.

The versatility of permanent magnetic couplings results from the many industrial companies that use fluid transportation and energy conversion processes, which include chemical processing; pharmaceuticals; power generation. Using this technology to its utmost potential means you should be focusing on proper components that match the performance required from your machines Torque, power & speed specification of applications being handled in-depth understanding can help us to configure any suitable magnetic coupling smoothly.

How to Use:

When you want to install a magnetic coupling, it is important that you understand how this works and what kind of things one has to follow under the guidance with an experienced mechanical design engineer for installation parameters. Reading all accompanying instructions and manuals are essential in getting the best use out of this toothbrush.

Service and Quality:

Although permanent magnetic couplings are long-lasting solutions, it is essential to keep them in pristine condition for optimal performance. Coupling components must be maintained to retain their design integrity through a maintenance schedule involving cleaning, inspection and repairs. Install QC testing and have access to expert support services for intelligent analysis or maintenance.

Magland Permanent magnetic coupling workshop spans 40,000 square metres fitted than 300 pieces high end manufacturing equipment, includes robotics well as automated machinery. facility allows precision effective manufacturing processes guarantee superior product quality.

Magland adheres strict quality control throughout entire production process. initial screening raw materials through final product inspection. product subjected extensive testing, ensuring they meet Permanent magnetic coupling well environmental requirements clients.

Magland puts great Permanent magnetic coupling technological advancement, collaborates partnership academic research institutions stay forefront technology magnetism. commitment ensures creation high-quality magnetic assemblies designed specific needs clients. requirements.

Magland offers customized services based upon magnetic circuit simulation software. Magland offers Permanent magnetic coupling customized magnetic solutions. product designed optimized meet particular requirements our customers. Additionally, commitment flexibility, company welcomes customization requests strives provide magnetic assemblies precisely line customer specifications.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd