-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

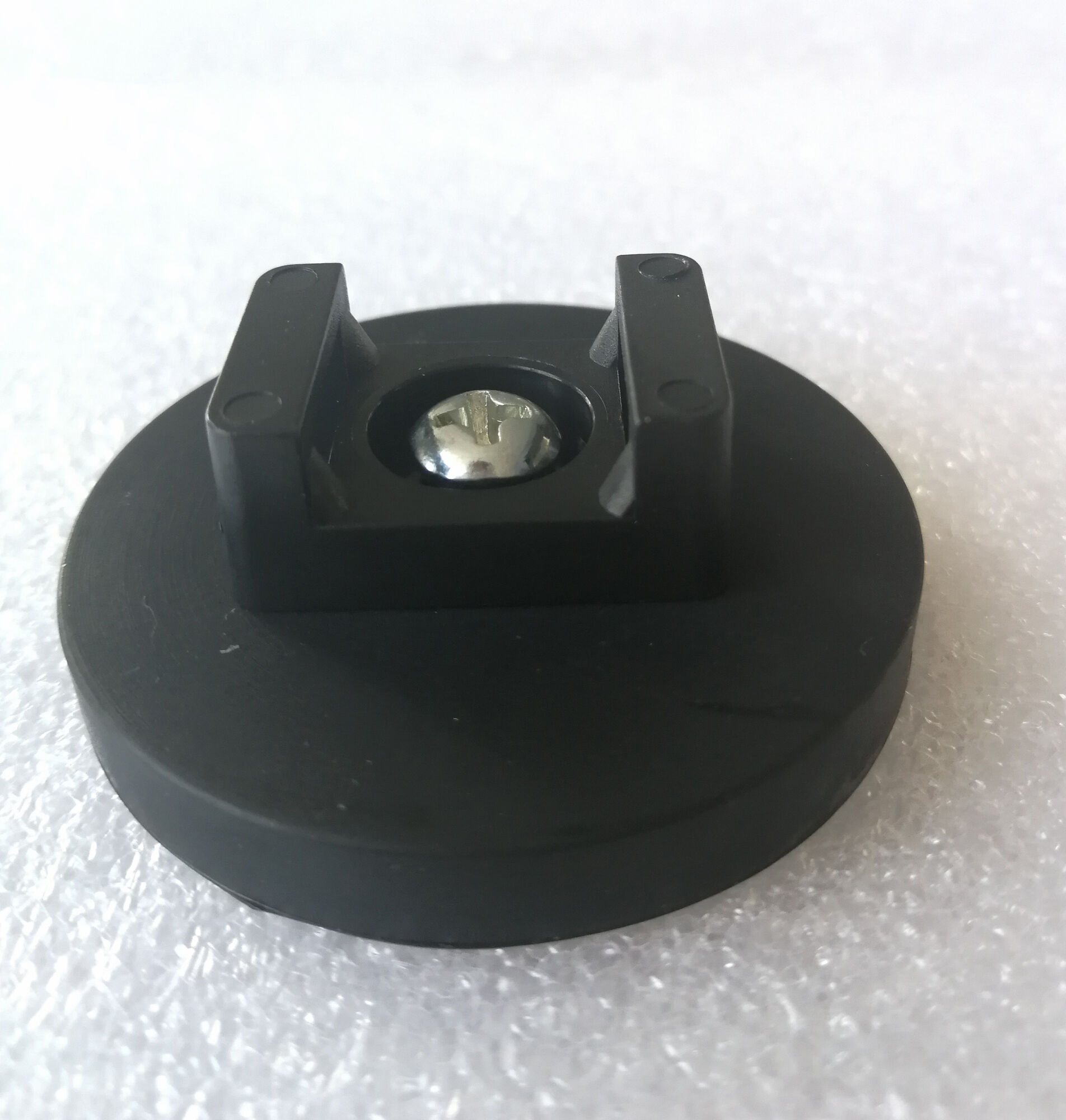

A Type of Magnetic Chuck for Lathe Machines - A magnetic chuck used in lathes is a special type of tool, it will properly fix the metal objects without using any clamps. This is a process that secures the workpiece during machining by magnetism. In this post, I want to share with you some significant details of the features, upgrades, safety tips, application and maintenance procedures as well quality parameters and broad utilization of magnetic chucks for manufacturing in lathe machine.

Benefits of magnetic chuck in Lath machine

Investing in a high-quality magnetic chuck for lathe machines is an excellent choice, providing a great return on investment to machinists and metalworkers alike, as well as the MagLand's lifting magnets for sheet metal. It provides a number of advantages which over competing standards for holding work effectively.

Magnet Chucks: Magnetic chucks never hurt a work piece so you are guaranteed to get elected the highest quality part. Secondly, it facilitates the handling of workpieces since they need no clamping as in traditional methods.

Magnetic chucks do their job on the lathe machines, but they have evolved over time, the same as magnetic lifter 500kg made by MagLand. A more recent innovation in this area is the use of materials that are tough at high temperatures with subsequent heat-intensive machining. Recent designs also offer better power and longevity, making magnetic chucks far more durable for precision machining applications.

When used properly, there are few risks of using magnetic chucks, similar to the MagLand's product like magnetic lifter 1 ton. Note: The workpiece must be clear of any metal debris before it is placed on a chuck. Chances of the workpiece shifting, while being machined are limited but still it is recommended to fasten well before starting.

The good thing is that using a magnetic chuck for your lathe machines is simple and involves few necessary skills, also the magnetic rod built by MagLand. You need to check dimensions of workpiece if it fits chuck or not. Make sure both the workpiece and chuck surface must be clean before putting it on. Before you start the machining process, align and secure it properly.

Since Magnetic chucks do not touch the workpiece, they only need simple maintenance, same with MagLand's magnetic chuck for milling. Clean the chuck of metal from wear and contaminants to maintain its holding power. It will be best to buy magnetic chucks which are manufactured by esteemed manufacturers for superior quality and durability.

Magland puts premium technological innovation works Magnetic chuck for lathe machine academic research institutions stay top developments magnetism. ensures innovative magnet assemblies created meet unique needs customers.

Magland adheres strict quality control throughout entire production process. initial screening raw materials through final product inspection. product subjected extensive testing, ensuring they meet Magnetic chuck for lathe machine well environmental requirements clients.

Magland Magnetic chuck for lathe machine workshop spans 40,000 square metres fitted than 300 pieces high end manufacturing equipment, includes robotics well as automated machinery. facility allows precision effective manufacturing processes guarantee superior product quality.

Utilizing magnetic circuit simulation software, Magland provides customized services meet clients' needs. Magland specializes customized magnetic solutions. product designed optimized meet specific requirements our clients. company flexible welcomes special requests. strives create Magnetic chuck for lathe machine assemblies precisely match client specifications.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd