-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

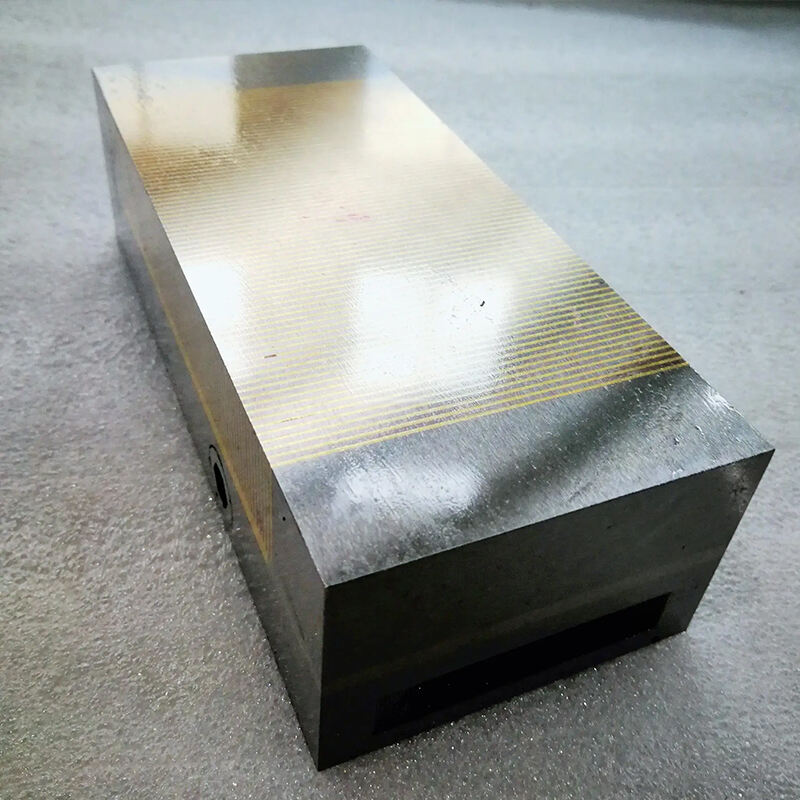

Any one who has been associated with metal works industries definitely shall know how essential it is to have the proper tools in order to get through the work. One of the most important machineries within the industry is known as magnetic chucks for grinding machines. This tool will perfectly hold the materials, and thus will work perfectly in keeping them in place as they get worked, maintaining them with maximum precision and accuracy.

In this paper, Magnetic chuck for grinding machine advantages, innovation, safety, use, how to use, service, quality, and application will be examined.

Magnetic chucks have a number of advantages over traditional methods. The greatest advantage associated with this is the fact that it firmly holds the material in place, thereby providing greater precision for the final result. This will help you fashion the materials into a more exact fine finish. Other advantages will include ease of operation, hence suitable for entry-level people in this particular industry. The magnetic chucks, being versatile at the most fundamental level, find application in a wide range of materials, including ferroalloys, carbon steels, and stainless steels, even on metal materials that don't have iron, such as copper and aluminum.

In the past, magnetic chucks have developed a lot. More efficient, versatile, and powerful designs have developed to meet specific requirements in order to suit all kinds of applications. Some have been designed to work with automated machines, thereby giving operators an easy time; this is because the machines load and offload materials effortlessly. Others have been made to work with high speed grinders. These balance between speed, power and accuracy so perfectly.

A magnetic chuck, being just another tool for use in the metalworking industry, requires a person dealing with it to take safety measures very seriously. The instructions provided by the manufacturer should always be followed, correctness in terms of usage and handling being ensured at all times by the employees. Further, even more care should be taken while dealing with large and heavy material matrices, as incorrect usage may result in serious injuries.

The operation of a magnetic chuck on the grinding machine is not that complicated if all the procedures involved in this operation are followed to the latter. Clean the magnetic chucks from dust or any other substance that may interfere with its performance. The chuck should be properly aligned with respect to the grinding machine. Now, place this work material on the chuck, and switch on the magnetic field to clamp the work. Finally, start the grinding operation without forgetting to gradually press the material to avoid damaging it.

Magland extensive workshops cover area 40,000 square metres equipped more 300 piecesMagnetic chuck for grinding machine processing equipment, such robotics automatic machinery. facility allows precision effective manufacturing processes, guaranteeing top quality products.

Magland committed Magnetic chuck for grinding machine quality controls throughout manufacturing process. raw material screening through final product inspection. products subjected extensive testing, order ensure they satisfy technical environmental requirements customers.

Magland offers customized Magnetic chuck for grinding machine based on magnetic circuit simulation software. Our company known providing custom-designed magnetic solutions, making sure product meticulously designed optimized fulfill individual requirements customers. company flexible accepts requests custom. strives create magnetic assemblies exactly match client specifications.

Magland strong focus development technology, cooperates research academic institutions remain forefront innovation Magnetic chuck for grinding machine. commitment ensures creation most cutting-edge magnetic assemblies, tailored meet clients' unique needs.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd