-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Permanent Magnetic Chucks are used for holding a workpiece during either grinding or cutting processes. They have a variety of advantages that can make it easier and more efficient to manufacture. Why Are MagLand magnetic chuck for grinding So Essential in the World of Metal Works?

One of the primary advantages of permanent magnetic chuck s is their ability to hold metal objects in place without requiring manual clamps or any other hardware. That allows workers to more easily handle pieces of metal without concern that the pieces are going to shift. Also, because the magnetic chucks hold onto the metal so securely, it can be a big help with the accuracy and precision of the work you are doing.

In metal work it is precision that counts. Permanent magnetic chucks aid in precision grinding, workholding, and finishing for industrial applications, holding metal workpieces in place for precision surface grinding, workholding, mounting, and finishing. This could also help to cut down on errors and waste, thereby saving time and money. Of course, since the magnetic chucks grip onto the metal so strongly, this allows for greater efficiency on the part of workers who need to work with this equipment, because they not to re-adjust pieces of metal that have become dislodged.

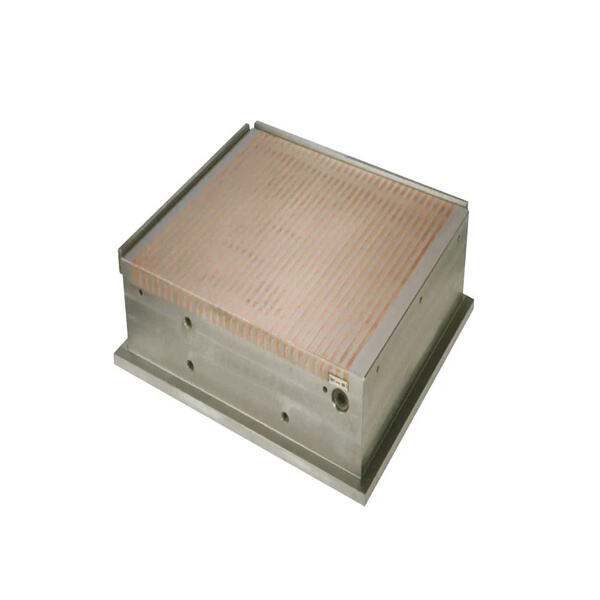

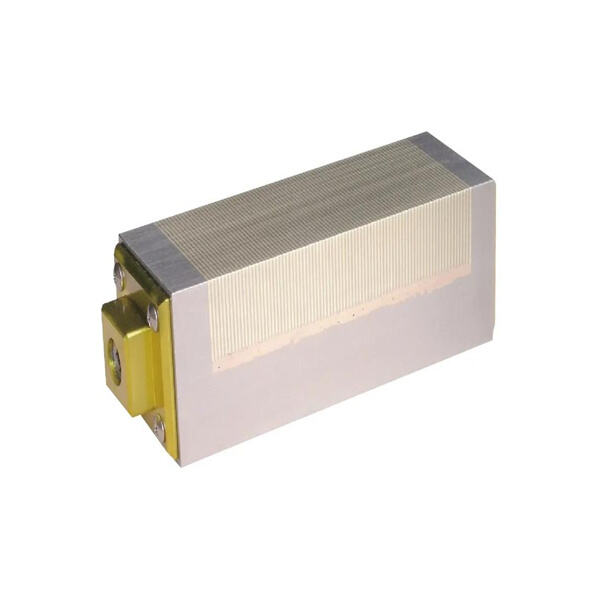

Types of permanent magnetic chuck There are many types of permanent magnetic chucks, each type of chuck will be designed for handling specific grinding tasks. Some of the magnetic chucks are rectangular in shape and some are circular or square. Here, some workholding chucks work with flat pieces of metal, while other types of workholding chuck work for round or irregular shaped pieces. It's essential to select the correct type of chuck according to the task at hand to achieve the best results.

Permanent magnetic chucks Corporate Chucks Permanent Magnet HR380 Permanent Magnet HR (Rectangular Type) Chucks: Business Will Power Machinery Co. Each chuck has been tested precisely for its accuracy ensuring high precision no power as their materials are magnets. They are constructed of durable material for daily use. And since they rely on magnets to grab onto metal, there are no moving parts to break or wear out over time. This makes them durable and dependable tool for any metalworking project with MagLand permanent magnetic chuck.

Caring for your Permanent Magnetic Chucks To help you get the most of your permanent magnetic chucks, you need to know how to treat and handle it properly. That includes maintaining the MagLand magnetic lathe chuck clean and free from any gunk, as buildup can impact their performance. Also, you need to keep them in the right place not to let them get broken. Occasionally checking the magnets’ hold and tightening screws when necessary can also help extend the life of your magnetic chucks.

Magland places high value Permanent magnetic chucks innovation collaborates academic research institutions stay top technological advancements field magnetism. ensures cutting-edge magnet assemblies designed meet needs customers.

Magland Permanent magnetic chucks workshop covers 40,000 square metres more 300 pieces high-end processing equipment, including robotics automated machinery. system allows precise efficient manufacturing procedures ensure superior product quality.

Magland committed strict quality control throughout production process. initial screening raw materials final inspection product. Additionally, all products undergo extensive testing compliant international Permanent magnetic chucks SGS, REACH, RoHS, PAH, CE making sure products meet clients' environmental technical requirements.

Permanent magnetic chucks provides tailored solutions based on magnetic circuit simulation software. Magland specialist providing customized magnetic solutions, ensuring product meticulously created optimized meet unique needs customers. company flexible welcomes special requests. strives create magnets meet specifications client.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd