-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Lifter magnets are powerful devices that can make lifting heavy objects a lot easier and safer. These special magnets harness strong magnetic forces to attract and pick up heavy objects. Below, we are going to discuss the cool tech behind Magnet Lifter and how they have revolutionised heavy lifting jobs.

Lifters magnetize a powerful magnetic field in order to attract metal items. However, when the lifter magnet is activated, it can easily pick up heavy metal objects such as steel plate, pipe or machine. The technology has been developed to extend the ability for workers to lift and move heavy objects without the need to use their own strength or large machinery.

Before the overhead lifting magnet was invented it was extremely hard to lift anything heavy and it took such a long time. Workers needed cranes, forklifts or another heavy equipment to move heavy metal objects. But when you have lifter magnets, lifting heavy stuff is as easy as pressing a button. This has revolutionized heavy lifting, making it faster, safer, and easier.

There are a lot of advantages when using lifter magnets that are related to safety and speed in great risk lifting jobs. One big advantage is that lifter magnets can be used to help keep workers safe. The magnets do the heavy lifting, so workers don’t have to hurt their muscles or put themselves at risk to move heavy items.

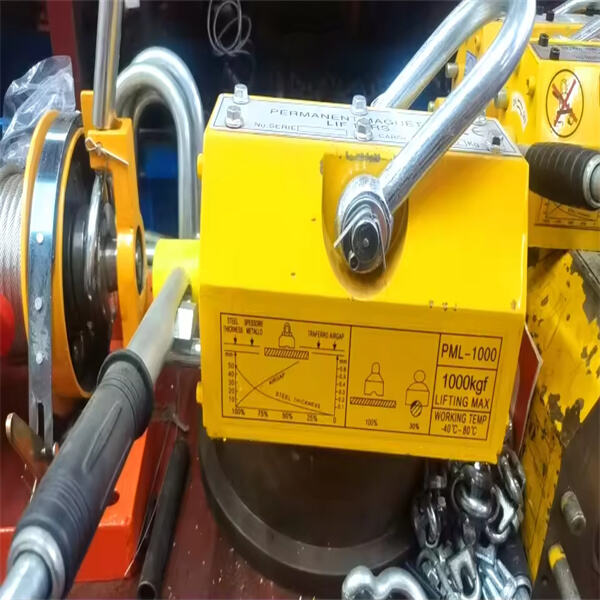

The magnetic lifter 1 ton also make heavy lifting faster. They can pick up and carry heavy items quickly, saving time and money. What that means is that companies can get their projects done more quickly and do better work.

There are as many types of lifter magnets as there are lifting requirements. Many of these lifter magnets are small and portable, making them ideal for lifting smaller, metallic items, such as tools. Other lifter magnets are larger and more powerful, capable of lifting heavy machinery or steel beams.

Next, you need to consider how powerful the magnetic plate lifter should be. Magnets, like all things, exist in various strengths so choose one that works for you. And, at el 3, just consider how large and heavy the lifter magnet is. Ensure that it is portable, easy to store, and use at your worksite.

Magland massive workshop covering 40,000 square metres Lifter magnet high-end manufacturing equipment, includes robotics well as automated machines. equipment allows precise efficient manufacturing procedures ensure superior product quality.

Magland adheres rigorous quality controls throughout step manufacturing process. Lifter magnet material screening final inspection product. product subject rigorous testing, making sure they satisfy technical well environmental requirements clients.

Utilizing magnetic circuit simulation software, Magland provides customized services meet clients' needs. Magland specializes customized magnetic solutions. product designed optimized meet specific requirements our clients. company flexible welcomes special requests. strives create Lifter magnet assemblies precisely match client specifications.

Magland Lifter magnet technological advancement works academic research institutions remain forefront advancements magnetism. commitment ensures cutting-edge magnet assemblies created meet unique needs customers.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd