-

Isitolo 1-2, Isidintsi 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Isitolo 1-2, Isidintsi 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

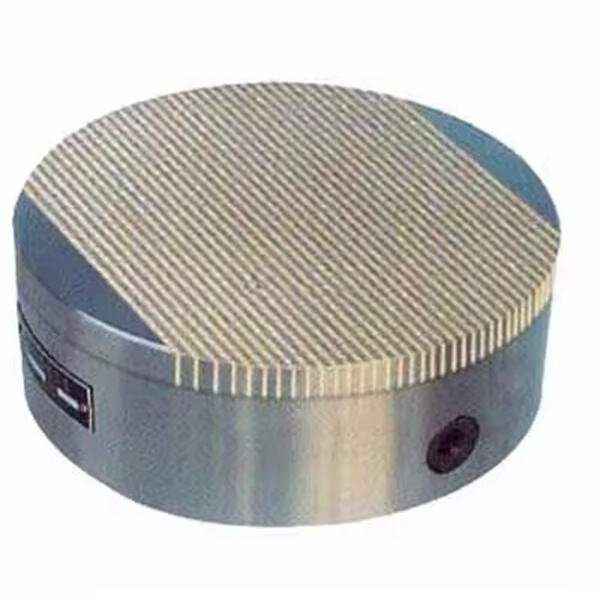

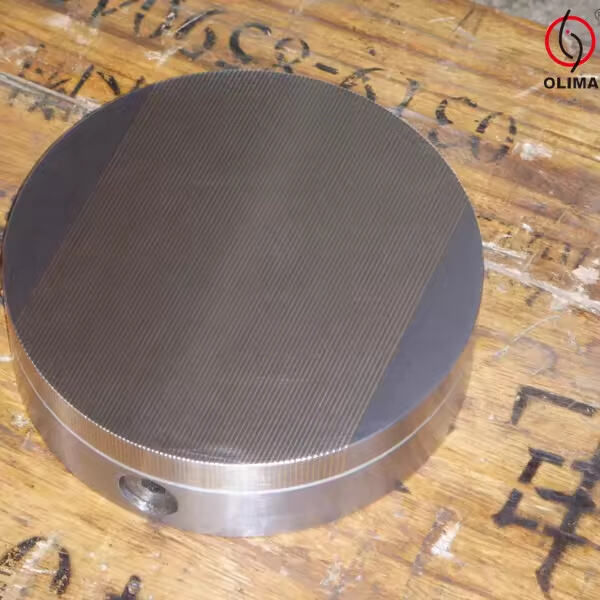

Iindlela ezingekeleni ngokomda njenge ipampe yomagane zisetyenziswa kakhulu kumhlambiso onobunzima nokuba zinto eziphawulwa ngokubanzi kumakhine emhlambeni imithi kwaye zeyona ndinga ezisetyenziswa ukugcina iphawu xa kudityaniswa umrhasi wokugqibela kwaye ke zemagnethi eziphemba kuzo kwaye ziphawula ngokuphelelweyo kwiwesi kwaye ziguqulela isantya xa uphatha kwaye inkonzo enkulu yoku sebenzisa iindleko zemagnethi ezijikelezelayo kukuba ziyahlula ubunzima bokusebenza kwaye ke ziguqulela iphawu ukunciphisa ukushakela, ukuze kusetyenziswe ukusebenza ngaphandle kokuchithwa. Umphathi obungqina nguukuba kuneempawu ezilungileyo kunye neenkcukacha eziphezulu.

Kunamaqela amaninzi xa kufundwa kwiindlela zokuchukumisa umgangatho wezilondo kunye nawe amacoupling omagane kwaye ukusebenza kwemali kwaye kukhawuleza kwaye kufudumeleyo ukusetyenziswa, yiyo ke yinto e suitable kakhulu yonke into yokusebenzela. Ukugcina okukhstronga ukuze ikhowudiyo ibe enye ng even during heavy machining. Oku kwenza ukusebenza kwemali kube better kakhulu ngokuhambelana ne efficiency kunye nokucacisa.

Iindleko zomgca weqhosha kunye ne isilondolozi Somoya zifudumeleyo kakhulu ukuseta. Cacisa kuphela i-chuck kwi table yakho yenxineke kwaye ufake umgca oqhosha ukuze ube khona kwaye i-chuck iyakhiwe ukusetyenziswa kwaye oku kwenza ukusetha ixesha kanye nekholwa lokuDluliselwa kancinane kwaye ngaphezulu oko, ukuthembekayo okuphezulu xa zisetyenziswa kwenza iikhowudiyo zibekwe ngokuphezulu kumachining esebenzayo.

Iindleko zomgca weqhosha zokudityanisa kunye ne indawo yokugcina yomagane ziyasebenziswa kwiindlela zokudityanisa ezityibilene nge rotary table kwaye ziyingceke kwaye zenze ukuxhasana phakathi kweyingceke kunye neyingceke ye tubular workpieces kwaye zenze isiqiniseko sokuba akukho ncedo okanye ukutshontsha kuya khona xa kudityanwa kwaye njengoko, i-part processed ichanywe ngokuchanekileyo kwiingcamatho ezilungileyo, ngoko ke yenziwa amagqibo angcono.

I-Circular Magnetic Chuck kunye ne uholder omagane isenokulaywa kakhulu kwiindustri eziphambiliyo zokwenza. Kwiindlela zokubhola nezokudlala, chucks ezi zisebenzisa ukugcina i-workpiece endaweni xa igqabi lesikhathini lifakwe kumoya kwaye inani leloye emva koko kube nenkcazelo yokucut, ukubhola okanye ukubhurula ngaphandle kwaye iingxaki ezinokuthunyelwa kakhulu kunye nokusebenzisa ngokukhawuleza kunye nokulula kuya kufuneka kuba khona ukwenza amachining eziphethe.

Indawo encinci yeMagland ikhupha iingxenzo ezinxulumene ngokomagineti iisikwelethi ezingu-300 kwiphumo leliphu elikhulu. Iindlela zokugcinwa kuyizinto eziphezulu zokwenza uhlelo olulodwa nokunjwa, ukuyidiliza imigca emifutshane yesimo.

Umqolo oqiniseleyo wokugcinwa kumgangatho opheleleyo ngoko kepha ukuya kwiindlela zokwenza. Ukuhlolwa kwamanani okuqala kuya kwiimpawu zokugcina. Iimpawu zikh subjected kwiimvavanyo ezininzi, ekunxileni xa eziphumana neengceke zokugcinwa kumgangatho zaseMhlaba.

U-Magland unikela iindlela zokuchukumisa umgangatho wezilondo ngokusebenzisa inkqubo yokuqwalasela umgangatho. Inkampani inomdla wokwenza amathiphu amathiphu asemthethweni, nokuthi impawu ichazwe ngokucacileyo ukuze iyisise isicelo seyeyona mntu. Inkampani inobunyefu obekhaya ukubona izicelo ezingenakho. Inceda ukwenza amathiphu amathiphu aphakathi nakumgangatho akuyona nje njengesicelo samakhasimende.

Iindlela zokuchukumisa umgangatho wezilondo zikaMagland ziyafumaneka ngokuba zifumanisa imithombo yokuphuhlisa. Ukudluliselwa kweba kunikeza amathiphu amathiphu asemthethweni anjalo ukuba ayiphumelele kuzithuba olulodwa lomakhasimende.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd